Description

At other products are

machinery elements that not need special presentation, that are standard parts

of various applications for decades. These products are made by European standards

DIN and ISO, in quality that has been recognized as good by our customers.

Usage

Usage

of standard machinery parts is founded in almost every application, in industry

and hobby. There has been used, in general, for transmission, positioning,

reduction of friction, sealing, protection, transport, esthetics, etc.

Types

Every class of products down indicated give essential parts of machines, plants, appliances, etc. There has been made classification to groups, depending of usage.

• Gears – Basic element of the gear transmission, it is possible to put in together with rack and/or other gear which create reduction, multiplication or simple transmission of the rotating force. Most common application that uses gears is packaging industry, graphic industry, production of reducers, etc.

• Racks – We found usage of racks when positioning, lifting or moving actions necessary, at utensil machines and other.

• Couplings – Usage of couplings is between e.g. electric motors and pumps or similar parts to absorb some of initiating torque that needs to be transmitted or low grade of eccentric to prolong work life of machines.

• Sprockets and plate wheels – Irreplaceable parts for chain transmission that is used at machines and transporters to provide high torque transmission.

• Chain couplings – Used as security part where high torque transmission is applicated to prevent damage and destruction of major parts.

• Pulleys - First half of belt transmission. Used when low torque is applicated, in general, pulleys are precisely, low noise and reliable way for transmission. Depending of application, we have V-pulleys, toothed pulleys, variation pulleys, multiway pulleys and others. Usage at agricultural machines, utensil and CNC machines, internal combustion engines, etc.

• Belts - Other half of belt transmission, depending on pulleys, it needs to be applied appropriate belt.

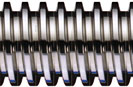

• Trapezoidal threaded spindles and nuts - Usage to positioning, lifting, pushing, puling, etc.

• Rod ends – Most common usage

at end of hydraulic piston because it provides non fixed movement.

• Cardan joints – Used where axes of motor and application are not well centered

or to provide distance necessary between two axes of transmission.

• Bushes – Most common usage at hydraulic elements or as replacement for bearing. Bushes are reliable when low rotation at radial movement.

• Bearings – Most outspreaded motion part in the world, at every application where some rotation exists, bearings are used.

• Bearing units – Support for bearing gives stabile and reliable way for fixing bearings at conveyors, drilling machines, circular saws, etc.

• Hydraulic components - tubes, pistons, end parts, O-ring seals, hoses, valves, distributors, etc. All needed for making e hydraulic units.

• Shaft seals and other

seal materials – Usage at all applications where prevention of entering dusts,

water, humidity, etc. or losing oil, water, coolant etc.

• Locking assemblies – Replace need for shafts with keyway to lock transmission.

Used to assemble shaft with e.g. pulleys, gears, etc.

• Equipment for transporters – Rollers, conveyor chains, belts, etc. Usage in graphic, packaging, food, drinks industry, etc.

• Industrial fans – Used to inhale or exhale fresh air in machines, plants, also at industrial filtering.

• Plastic caps – Used for protection of tubes, threads, etc. Also for esthetic reasons.

• Rubber shock absorbers – Used at machines which have problem with vibrations and punches.

• Linear guide components – Used at machines for precisely linear movement, positioning of cutting, laser, etc.

• Pumps – Used to create flow for cooling or pressure where needed, for distributing or moving liquids.

• Industrial glues and chemical products – For sealing, pasting, protection, decoration, cleaning, securing thread, lubrification, etc.

• Cable chains – Used to provide

quality movement of hoses, electrical cables or other without damaging and

to prolong work life. Most common usage at machines which have linear movement

so that cables don’t disturb function of machines.