Description

Endless

worm spiral or helical conveyors are the best and most economical way to transfer

bulk and powder cargo where is need of large amount of material transferred

in a short time. The most common materials that are transmitted with worm

transporters are: wheat, corn, salt, sugar, flour, pellet wood for heating,

mineral fertilizers and other such materials. In case of need precise dose

of material, endless worm coils are the ideal solution because it is very

easy to calculate the amount transferred, with the help of data like a diameter

and pitch of the coil, slope and speed of rotation.

Sabbadin Croatia is representing Italian producer of the endless worm spirals for Croatian market and has some quantity of various outer diameters at warehouse in Sesvete.

Usage

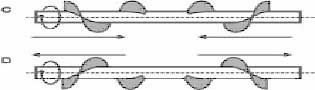

Variations in production of the endless worm coils considering needs of the

customer and technical solutions of the helical conveying:

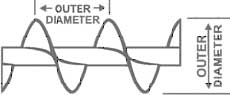

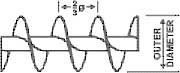

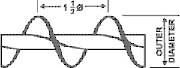

• Standard, outer diameter and pitch are the same. This is most common used type of worm coils.

• Reduced pitch compared to outer diameter. This type of worm conveyors is used for production of mixers and conveyors with slope higher than 20°. This type of worm coils are made with pitch reduced to 2/3 of the outer diameter for sizes Ø 300 or smaller, if higher, pitch reduces even more.

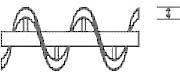

• Endless worm conveyors with extended pitch comparing to outer diameter. This type is used for fast conveying and for mixers that mix liquid. Extension of the pitch is 1,5 times higher when compared to outer diameter.

• Endless worm coils made of stripes. Used for viscous or damp material, transportation for snowplow. etc. Sticking between coil and shaft is avoided.

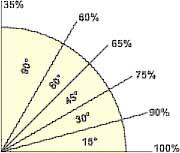

• When conveying with endless worm coils, one of key facts is slope. When slope is higher, it's reduced amount of material transported considering working hours. Other factors are: type of material, humidity, outer diameter, load and speed of axe. In the diagram is indicated reduced percentage of the material transported and in a table is indicated example of conveying wheat with coil Ø80 mm of outer diameter, Ø100 mm diameter of the tube and speed approx. 700 rpm.

Types

Endless worm spirals are produced in two most common materials, carbon steel

and stainless steel.

• Standard delivery length of endless spirals is 3 meters (L=3000, ± 2%).

• Standard production

starts at Ø 50 of outer diameter and goes to Ø 500.

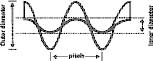

• Pitch is, as already

said, equal to outer diameter in most common situations but if customer is

seeking otherwise, it will be made as wish of customer.

• Inner diameter is approx.

1/3 of outer diameter, but this is convertible and depends on thickness of

the strip that has bin made of.

• Thickness of endless worm spiral is varying and in inner diameter is approx. twice of thickness compared with outer diameter.

• Endless worm spirals can be delivered

in two rotation direction, left and right, but most common used direction

is right-handed.